|

I was asked about forest regrowth after a fire, or any disaster really. Why do they grow back different from what they were originally?

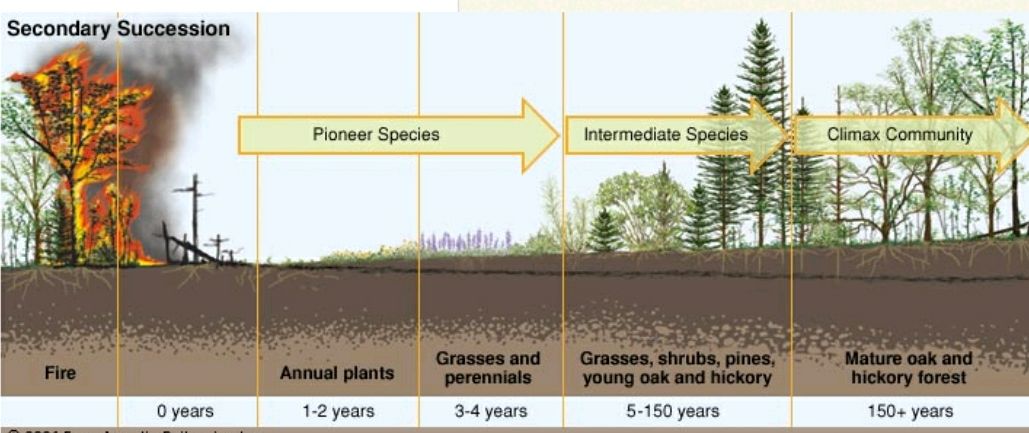

I've been doing some research, it looks like it's just a high degree of random effects. When a fire sweeps through a forest what regrows is called Secondary Succession. The picture up top helps illustrate this process. Pioneer plants quickly take hold and gradually change the landscape. Dependant upon which seeds spout first can change how much of the ground is shaded and the soil composition thus possibly creating a new set of conditions with new plant growth as the return of the forest begins. Many times even as fires are tearing through a forest, the start of new tree growth is already happening. The heat from the burning trees pops open the cones on those trees, releasing seeds that have been waiting to get loose for years. Within 30 or 40 years, many won't even be able to tell there was forest fire there. Scientist say that fire is a natural part of the forest’s regeneration system and that most forest trees need to be exposed to fire every 50 to 100 years to invigorate new growth. But as I said above, it's a high degree of random effects. Weather patterns can also play a big role in how the new forests develop. If there is a drought after the fire, that could kill the newly released seeds and short-circuit any new growth, giving new species of trees a chance to grow in the area. Normal rains mixed with the nutrients left on the ground from the fire could be a great booster shot to getting the seeds off to a flying start. I'm not sure how helpful this was, I certainly learn something new though! Hope you did too!

0 Comments

They say in Indiana, there's only two seasons, Winter and construction. This usually pertains to road work, but we've jumped on the construction bandwagon... We have made the leap and are expanding! We thank you all for making it possible! It's because of you, our loyal customers that we are able to do this and better serve you!

I'm sure most of you have seen our social media posts with pictures of this monster of a machine, or have been out to the mill recently and seen it. I thought I'd take a little time to explain what it is and how it'll benefit you. For those that don't know, this is a grinder, it does just what you'd think, grind up wood into chunks. It will save us time in the process of using this one compared to what we've been used to, but best of all, it will help us keep up on demand of sawdust, and mulch! No more trips to see us and leaving with any empty bed! We do ask though, that as this is new to us, that you do give us time to tweak all aspects of providing for you. This doesn't mean anything chances for you in the mean time. Unfortunately this will be like the other equipment and we will not be able to have you back to watch the process, but maybe we can get a video uploaded soon once we have everything ready to go. This was posted on our Facebook page last year, but since we are back into the season of mulching (if it ever stops raining!) we thought maybe this would be a helpful tool to post again, and hopefully will be able to reference it quickly year after year.

We are in no way affiliated with this website but found this to be helpful and thought we'd share it. It tells you how to's, a mulch calculator, FAQs and there is also an interactive tool on there. You can chose your house color (it's only the most common exterior colors) and then you can choose the different colors of mulch to help you visualize what it will look like. As you can see, we offer 5 different mulches; Black, Red, Dyed Dark Brown, Double Ground Brown, and Single Ground Brown. Both the Double Ground Brown and the Single Ground Brown are natural mulches with no dyes. The only difference between the two is that one has been ground up twice for a finer mulch, while the other has only been ground once for larger pieces. Here are some helpful tips about colored mulch: -Mulch should slope away from homes and buildings for proper water runoff. -Mulch should be installed on a day when no rain is in the forecast for 24 hours. -Mulch will still be damp upon purchase and will not dry completely until spread in a landscape setting. -Once dry, the colorant bonds to the mulch so it won't wash or leach. -Use a tarp if unloading, as damp mulch may stain concrete or asphalt -Do not apply mulch during rain. We sell our mulch by-the-yard. Our current pricing is $37.00 per yard for the Black, Red and Dyed Dark Brown. $33.00 per yard for the Double Ground Brown, and $23.00 per yard for the Single Ground Brown. *these prices include tax. We will also deliver mulch to your home or business, we can deliver up to 20 yards at a time. We charge $2.50 a mile, with a $30.00 minimum. Feel free to call us if you would like to schedule a mulch delivery or have any questions! We asked for our customers to share some of their projects they have been working on, and the response/projects blew me away. Hope you enjoy these pictures as much as we have. Thank you to everyone who shared your projects with us. *Due to the nature of some of these projects, as well as customer privacy, names have not been released. **If you still have pictures you would like to send in, you may do so, we will try to feature them at a later date. Japanese Spa Live Edge Bench Multiple Red Oak Projects for a church in South Carolina Accent Beams Tiny House "Barn Door" Walnut Live Edge Table Top Oak Chair Rail

Awhile back we posted pictures to give you an idea as to how our sawmill operates, Well hopfully this blog post will give an idea as to what our millwork building does. Most of our material that is stocked in our warehouse is rough sawn lumber. We can mill the material to your specifications though. We are able to do surfacing, sanding, and straight line rip, if small quanitites we can even do it while you wait. We can also do most any custom millwork. Give us a design and measurements and we'll see what we can come up with. Our machines are only so big however, below are the sizes in which some different machines can handle: Sander - 1/8" minimum thickness - 4 3/4" maximum thickness - 36" maximum width Planer - 1/2" minimum thickness - 16" maximum thickness - 25" maximum width Straight Line - 1/4" minimum thickness - 5" maximum thickness - 48" maximum width I have included some pictures below of some different custom projects we've done in the past.  Heat Treating Heat treating is a process with the end goal of removing living organisms from wood products to make them ready for shipment or export. During this process wood, is brought to a temperature of 132.8 degrees or above and held there for 30 minutes. This kills any bugs so that the wood may be exported. After heat treating, the lumber or crating is stamped to certify that the process has been completed and it is then ready to ship. Heat treating is a completely different process than kiln drying. Kiln drying removes the moisture content of the lumber, while heat treating kills any organisms inside.  Kiln-Drying Kiln-drying is a process which involves applying heat to lumber for a specified period of time in order to obtain a desired low moisture content (normally 6% or less, depending on your application). Hollingsworth Lumber has been providing kiln drying services for over thirty years. Kiln-drying is a better alternative to air-drying because we keep the lumber in a controlled environment and do not allow it to dry too quickly. Also, most air-drying applications do not dry lumber below 18%. Kiln-drying is more time consuming depending on species and thickness of the lumber you are drying. When kiln-drying, lumber is stacked on sticks in order to allow circulation around the boards. These pictures are posted on our Facebook page in an album also (along with a couple others that didn't make it here), but we often have people ask us about our process here and how we operate. Unfortunately due to insurance reasons we cannot show people what goes on in the sawmill or millwork buildings. Hopefully this gives you a better idea as to what all goes on to get you your lumber. I hope to bring you a blog post about our millwork building and capabilities soon- keep an eye out!

I'm sure many of you by now have your Christmas decorations up. But incase you're like me and haven't had time to even think about when you will be putting them up, here's some interesting facts about Christmas Trees that may help you decide which to choose!. And for the rest of you, it can just be some fun facts, or somthing to think about for next year! Below are the most common types to grow in Indiana, (for a more extensive list, visit The National Christmas Tree Association website.)

Here's some tips and tricks for caring for your new Christmas Tree:

.And remember your real Christmas Tree is a recyclable and renewable resource. Trees can be converted into useful mulch after the holiday season and many other craft projects!

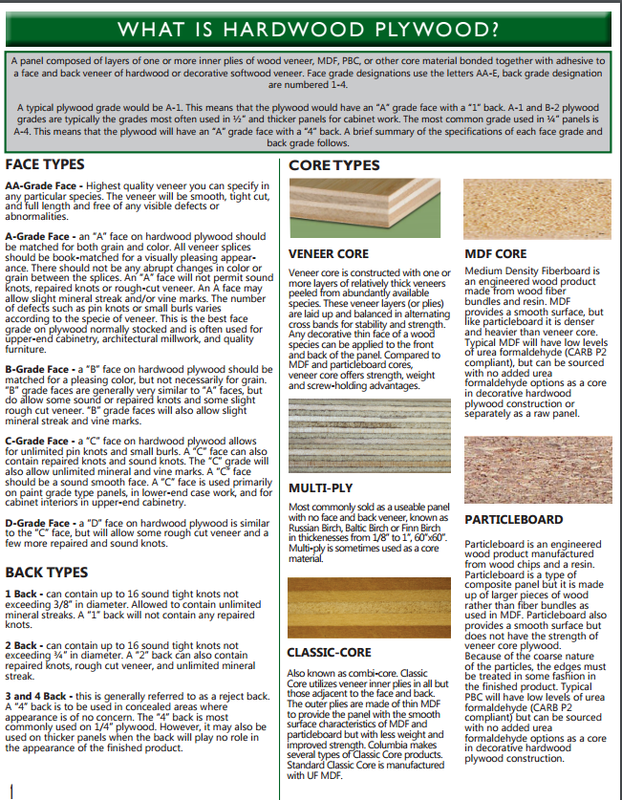

For more information or facts visit http://indianachristmastree.com/pages/facts.php Merry Christmas and Happy New Year from all of us at Hollingsworth Lumber ! We have many questions about plywood and what the letters/numbers mean. Here is an article that explains the different types of plywood as well as the grading of the plywood.

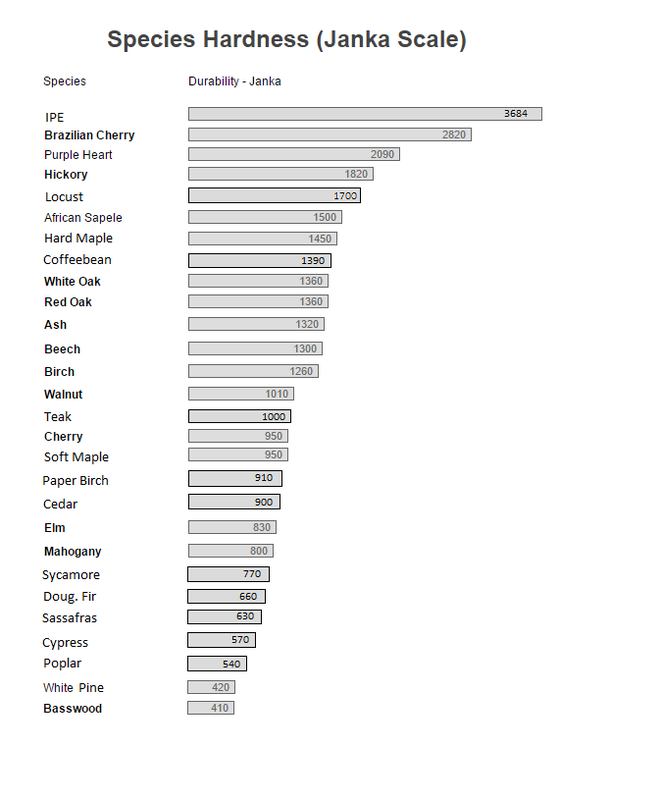

Am I the only one who thinks of Jenga (you know the Hasbro "How do You Stack Up?" wooden block game), when someone says Janka? At least it isn't a too far off connection between the two, Janka is the hardness of woods. The Janka Hardness Test measures the resistance of a wood to denting and wear. The higher the number, the harder the wood. These ratings are determined by the force required to embed a .444 inch steel ball to half its diameter into the wood. There are many other woods, but our most commonly sold are listed on the Janka Scale below for you to easily compare. |

AuthorFrom everyone here at the mill, we will post about what has been going on around here, any interesting facts we may have for you, or an answer to a question that has come up. Archives

January 2018

Categories |

RSS Feed

RSS Feed